At first glance, it may not appear that a PLC enclosure will be a crucial factor in the design of your electrical system. However, it becomes clear that these boxes play a crucial part in protecting against humidity, moisture, and temperatures.

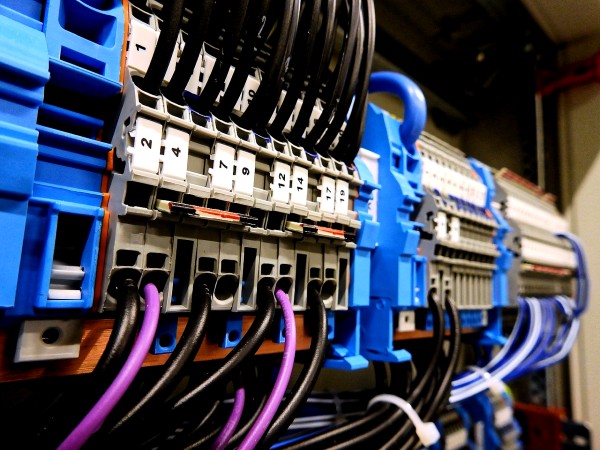

This is particularly true if you consider that a PLC enclosure can also contain power supplies, switches, routers, microcontrollers, fiber optic devices, electrical wirings, and other parts.

Source

Moisture and overheating can shorten the lifespan of the equipment that you have to protect. This leads to major system failures and the potential of electrical shock to users.

A PLC enclosure can help guarantee long-term reliability and proper operation of all protected parts.

A PLC enclosure should be made from high-quality materials. It should provide shatterproof safety, scratch resistance, and impact resistance.

The materials should also offer weather resistance, UV ray protection, corrosion resistance, and temperature protection in a huge range of environments.

While most PLC enclosures are manufactured with indoor applications in mind, they can also be extremely useful for outdoor applications.

Here are some of the biggest benefits of having a PLC enclosure.

High-Quality Materials

When choosing a PLC enclosure manufacturer, you’ve got to guarantee you purchase an enclosure from a reliable manufacturer.

The manufacturer should pride itself on being able to provide high-quality PLC enclosures for a cost-effective price.

As a client, you need to make sure you get peace of mind knowing that your PLC is safe. If you choose a PLC enclosure that is made from high-quality materials, you’ve got nothing to worry about.

Fire Resistant

Source

A PLC enclosure should always be fire-resistant. A reliable manufacturer will always test the enclosure.

According to professionals, a premium PLC enclosure should withstand fires with temperatures above 1000°C.

Furthermore, a PLC enclosure should always be non-combustible. With this, you will have peace of mind knowing that your PLC is safe in case of fire in your company.

Cost-Effective

For those who don’t know, it is more cost-effective to utilize a steel enclosure in the long run instead of utilizing another form of enclosure.

You might notice that the initial purchase cost is a bit higher compared to other types of enclosures. However, you can guarantee that a PLC enclosure will last for a long period with less maintenance needed.

Installation of a PLC enclosure is simple and quick as well.

Eco-Friendly

Source

A PLC enclosure lasts longer compared to other enclosures out there. This includes plastic or wood framing. It’s both light and easy to move around. A PLC enclosure also generates less raw material waste.

PLC enclosures are simple to clean. This makes them the best option in a lot of processing and manufacturing facilities.

When the PLC enclosure reaches the end of its lifespan, the manufacturer of the enclosure can recycle the materials and use them to create new PLC enclosures.

Safe and Durable

PLC enclosures are resistant to corrosion, pests, and fire. The enclosures can endure severe conditions in the environment, such as wet climates and extreme hot temperatures.

A PLC enclosure is also resistant to scaling. They can retain their strength at high temperatures. Steel portrays great stoutness at cryogenic temperatures.

PLC enclosures don’t need treatment with preservatives or pesticides. That is why they’re safe for persons handling and living around them.

So, before you search for industrial robots for sale, make sure you install a PLC enclosure first.

NEMA Ratings

Source

Most people are referring to the enclosure ratings when talking about the various types of PLC enclosures. These ratings are defined by the NEMA (National Electrical Manufacturers Association).

For those who don’t know, NEMA is the organization that defines the standards for electrical enclosures in North America.

The rating is typically known as the NEMA rating system. To enhance the reliability and safety of their products, most manufacturers in the US design their enclosures to meet these standards.

Purpose of NEMA Ratings

A NEMA enclosure is an enclosure that has been manufactured to meet one or more particular standards in the NEMA ratings.

NEMA ratings indicate the ability of a PLC enclosure to endure particular hazards and environmental conditions.

For instance, a utility company housing their fragile electrical systems outdoors in a coastal region might have to use a NEMA 4x enclosure to protect against corrosion and weather.

Material Types of PLC Enclosures

Source

Aside from NEMA ratings, PLC enclosures also come in various materials that can greatly influence their performance and function. Here are some of the most common base materials that manufacturers use:

Carbon Steel

Carbon steel PLC enclosures are cost-effective and strong. Unfortunately, they’re extremely prone to rust. Thus, you should not use them in coastal regions where salt in the air can wear down the enclosure easily.

Stainless Steel

Just like most enclosures, there are pros and cons to stainless steel PLC enclosures. While it’s fire-resistant, it’s a heavy material that is more expensive in general compared to other materials.

Aluminum

Aluminum PLC enclosures are more expensive compared to plastic PLC enclosures. However, they provide a lot of advantages.

Aside from being very durable, aluminum PLC enclosures can also endure high temperatures. They’re also extremely resistant to corrosion.

Polycarbonate Plastic

In general, polycarbonate plastic PLC enclosure is a lot cheaper compared to other materials. It also has better impact resistance.

Aside from that, polycarbonate is also suitable for a huge variety of outdoor and indoor applications.

Due to their cheap price, this type of enclosure is commonly utilized in the IT industry and some trade show rentals Las Vegas.

Conclusion

Since we are quickly progressing when it comes to technology, we are beginning to place electrical systems in a range of nontraditional environments.