Running any business operation today can be challenging for both the employer and the workers that perform a wide range of essential tasks. This is because some problems experienced or encountered in the production of products can be inherent and may cause issues that need to be resolved right away.

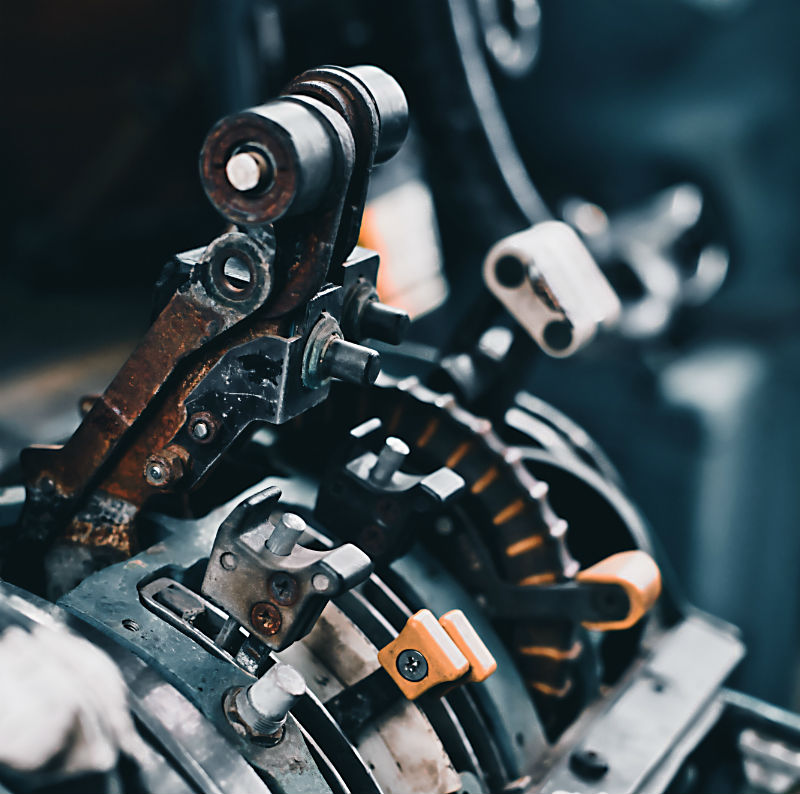

This is especially the case for those of you who may be working in an industrial or manufacturing setting that deals with the wear and tear of machinery that produces auto parts for car dealerships and auto repair shops all over the globe. In fact, because there are some issues that these plants experience, it is important that they are addressed early on so that it will not only save employers and management but money too.

Having said this, if you need a solution that can effectively solve the wear and tear problems of manufacturing auto parts that you are dealing with on a regular basis, here are four things that you should know about and a solution that is called wear plate technology.

1. Downtime of Industrial Machinery Results in Production Loss

When you are operating a manufacturing company, there are a wide variety of things that you may be looking for to ensure your operations are always running smoothly and effectively. In some cases, you need an added layer of help and protection to maintain the machinery to keep it from always breaking down prematurely, especially since the repetitive actions of the equipment used cause wear and tear that is difficult to avoid unless you find the right solution. This is also one of the main reasons why you should incorporate wear plates that can help extend the life of the machinery used in the process of making auto parts or other products.

Wear plates are being designed for a number of different reasons, including being made for extended durability. For more information about auto parts production and other key information, it is important that your homework on how this technology actually works today.

2. Wear Plate Technology Helps to Resolve the Downtime Problems

To keep a manufacturing machine running properly, these machines need to be maintained and repaired by experts that know exactly what needs to be done. This includes making sure the machine parts are restored and replaced to prevent them from breaking down, to ensuring issues are identified and addressed before the operation is adversely affected by unnecessary downtime.

The role that these technicians play can be all-encompassing, including replacing old technology with the newest technology in wear plates. Whatever the case or situation, the main goal for companies like The A.J. Weller Corporation is to use this technology to not only save plants time but also to help them save money in eliminating unplanned time off of the job.

3. Advanced Wear Plate Technology Helps in Meeting Growing Demands and Productivity

Based on the product needs of a customer that a manufacturing company supplies, the demand for auto parts can be quite high over a period of time. Therefore, all of the parts that they need to produce to meet the needs can even have a huge impact on the volume that is needed. For instance, the repetitive motion that it takes to make these large volumes need to be anticipated well in advance.

In fact, if the expectations tend to be more than projected, the wear and tear will automatically mean that the entire operation will be adversely affected in one way or another. On the other hand, with the use of the newest technologies in advancing wear plate technologies, these companies are more than able to meet the growing demands without disruptions. To help the average person to understand how this technology is impacting manufacturing as a whole, they might start with the basics on how these manufacturers are utilizing it to their advantage.

4. Wear Plate Technology and Extended Life

You should know that wear plate technology helps in other ways that are needed too. One of the most important involves the machine’s life extension due to the wear plates impact providing more durability. Therefore, when technicians are concerned about how long their machines and their own parts will last during the manufacturing process, they can expect to see an extended life and a good investment for the machines that they repair and maintain.